Aug. 22, 2022

A propeller is a special type of fan that converts rotational motion into thrust by producing a pressure difference in the surrounding fluid. Standard fans and propellers have the same physics, yet a fan is generally stationary whereas a propeller causes the object to be in motion. Propellers are a major component in a number of industrial designs concerning rotating machinery. The key mission in designing a hydrodynamic or aerodynamic propeller is ensuring efficiency.

LY-70KGF Thrust Stand and Dynamometer

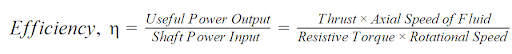

Propeller design efficiency is judged by the useful power output it produces. For example, the useful power output for a fan is how quickly the fan can accelerate the surrounding airflow. Due to their dynamic nature, propellers’ efficiency is instead measured by thrust developed on the blades and how this powers the respective system, whether it be a boat, plane, or other application. To work out the true efficiency, the following equation is used:

Where:

● Thrust in N

● Axial Speed in m/s

● Resistance torque in Nm

● Rotational Speed in rev/s

Design parameters can impact the performance of the propellers or fans. These variables can include the number of blades needed, the size of the outer diameter, the pitch-affecting angle of attack, as well as the leading and trailing edge blade angle along with many others.

The diameter of the propeller has a significant impact on its efficiency. Larger propellers have the capacity to create more power and thrust on a larger fluid volume. Yet, most designs face limitations when it comes to diameter, so optimization must occur elsewhere.

Increasing the number of blades will actually reduce the efficiency of the propeller but with a higher number of blades there is a better distribution of thrust helping to keep the propeller balanced, therefore a trade off must be established.

The presumed velocity of the fluid flow, whether it be air or water, is another important variable to consider. This force, along with the velocity of rotation (RPM) determines the pitch distribution of the system. Large propeller designs can become less effective operating at the axial velocity. The most efficient designs are those which maintain a pitch to diameter ratio of 1:1.

While the actual density of the fluid has no effect on the efficiency of the system, it does play a role in defining the shape and size in the early phase of the design process. For example, an air propeller used for planes and drones will have a bigger face than its aquatic counterparts, as the fluid density is less.

Instead of the standard lift and drag coefficients, ensuring propeller design efficiency requires specific airfoils with prescribed angles of attack at each radius. The distribution of Cl (lift coefficient) and Cd (drag coefficient) along the radius can be examined by performing analysis for the design point. For maximum efficiency, the airfoils must operate at maximum L/D. If the propeller should also work fairly well under poor conditions, it is usually necessary to use a lower angle of attack for the design.

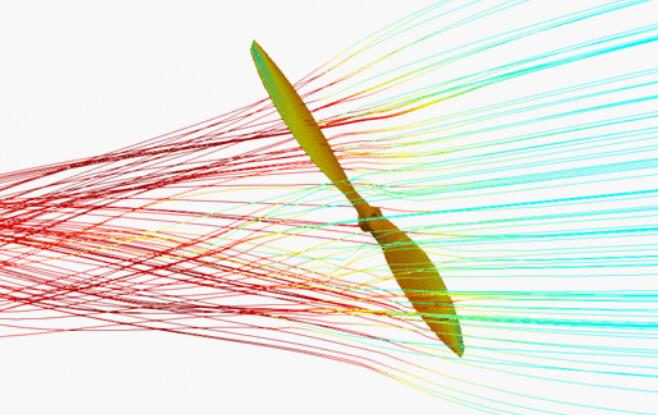

We simulate a propeller design at multiple RPMs. Multiple factors including the airflow over the blades, the resulting turbulence, and performance indicators such as torque, axial thrust, and velocity were evaluated.

The simulation measured the useful power, or thrust, resulting from the input power, or torque, acting upon the propeller.

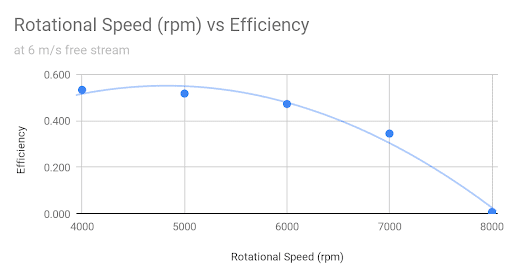

At specific and fixed free stream velocities, 5 different RPMs were tested to evaluate their respective efficiency. As exhibited below, the simulation found that the propeller design was the least efficient at the highest RPM, and should operate around 4000 RPM for best results.

Using online simulation, it's easier than ever to be able to use CAE technology to preemptively test design iterations before prototyping. For fan or propeller design, this is especially true as the testing of different RPM speeds is crucial to ensuring a design's overall efficiency.

E-mail: sandy@wing-flying.com

Add.: 7th Floor, B2#,Animation Building, Sino-Singapore Tianjin Eco-City