Jun. 14, 2025

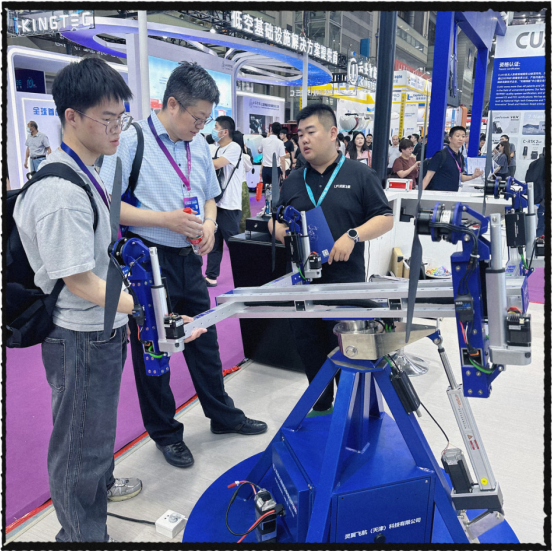

In the surging crowd of Shenzhen UAV Exhibition, we not only shook hands with old friends who walked side by side, but also welcomed many new partners who explored the forefront of the industry. Behind the roaring engine and the spinning blades, a storm of innovation about the core of WING FLYING's UAV power system - motor, engine and propeller precision testing technology, is quietly rising at our booth and has been successfully converted into on-site orders, confirming the market's urgent need for high-precision testing solutions.

"Full body checkup" of the power heart: motor and engine test equipment are showing their edge.

Facing old customers' inquiries about product performance upgrades and new customers' concerns about quality control, our integrated UAV power test platform became the focus of the whole venue:

*MET-V6 multi-dimensional performance map: dynamic loading system accurate real-time data and real-time test data curves, real-time drawing of torque-speed-efficiency and other maps, revealing the "true character" of the motor/engine in a complex environment.

*Extreme endurance challenge: continuous high-load operation test chamber, equipped with infrared thermal imaging monitoring, so that overheating hazards and efficiency attenuation points have nowhere to hide, ensuring the power heart lasting surging.

*Smart energy efficiency diagnosis: The power quality analysis module deeply analyzes the input/output power curve, accurately quantifies the loss link, and provides data for customers to optimize energy design.

After experiencing the test demonstration, the technical director of a leading industrial UAV company on site exclaimed: "This system allows us to foresee the bottleneck of motor life in the R&D stage, and the efficiency improvement path is clear at a glance." The purchase agreement for two high-power motor test benches was signed on the same day.

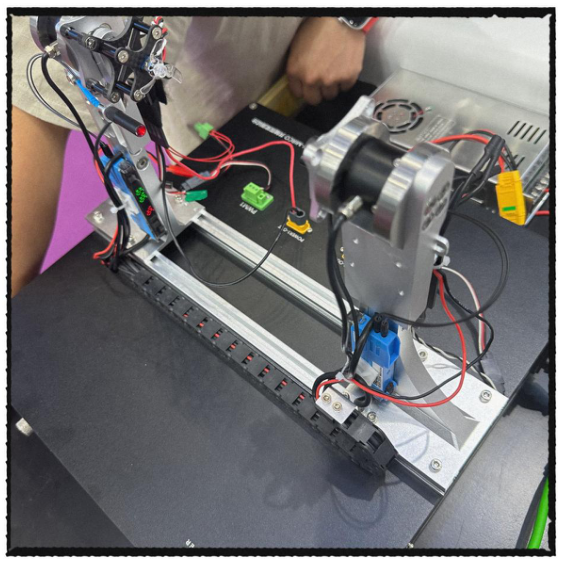

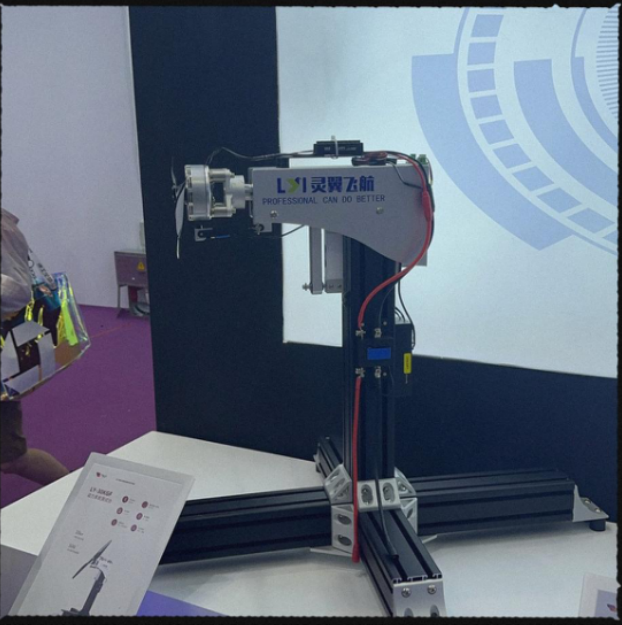

On the other side of the booth, LY-QZ-F4-10kg Thrust Test Stand------Quadcopter unmanned aerial vehicle test bench:

Facing old customers' inquiries about product performance upgrades and new customers' concerns about quality control, our integrated UAV power test platform became the focus of the whole venue:

MET-V6 multi-dimensional performance map: dynamic loading system accurate real-time data and real-time test data curves, real-time drawing of torque-speed-efficiency and other maps, revealing the "true character" of the motor/engine in a complex environment.

Extreme endurance challenge: continuous high-load operation test chamber, equipped with infrared thermal imaging monitoring, so that overheating hazards and efficiency attenuation points have nowhere to hide, ensuring the power heart lasting surging.

Smart energy efficiency diagnosis: The power quality analysis module deeply analyzes the input/output power curve, accurately quantifies the loss link, and provides data for customers to optimize energy design.

After experiencing the test demonstration, the technical director of a leading industrial UAV company on site exclaimed: "This system allows us to foresee the bottleneck of motor life in the R&D stage, and the efficiency improvement path is clear at a glance." The purchase agreement for two high-power motor test benches was signed on the same day.

At the same time, over a hundred new customers have left deep cooperation intentions, involving emerging fields such as emergency rescue and logistics distribution.

The 2025 Shenzhen World Drone Exhibition was a complete success. See you next year on time, our dear friends!

E-mail: sandy@wing-flying.com

Add.: 7th Floor, B2#,Animation Building, Sino-Singapore Tianjin Eco-City