Feb. 14, 2026

(Including Requirements for Test Models, Equipment, Procedures, Data Processing, and Report Writing)

This article introduces the group standard “Technical Specification for Drone Propeller Matching Test” co-authored by WingFlying.

This document specifies the testing methods for propeller matching technology, including:

Test models

Test benches

Testing procedures

Data processing requirements

Experimental report writing requirements

It also provides explanations of propeller matching technology, precautions during testing, and case references.

This document is applicable to matching tests of propeller power systems (including propellers, engines or motors, and control systems) for large, medium, small, and micro unmanned aerial vehicles with a maximum takeoff mass of less than 500 kg.

The following terms and definitions apply to this standard. The terms defined in GJB 4296-2001 and GJB 4395-2002 are also applicable.

Matching refers to the process of pairing a selected fuel engine or electric motor and its control system (hereinafter referred to as the drive system) with a propeller based on the flight conditions of the UAV.

The matching assessment includes verifying whether:

The complete power system can operate under specified flight speed, altitude, and other conditions

The system performance indicators meet design requirements

Specific fuel consumption refers to the fuel mass consumed per unit of effective power generated within one hour. It is one of the main parameters used to describe the fuel economy of an engine.

Total power refers to the overall power consumption of the UAV power system during operation.

Shaft power is the portion of the UAV power system that converts other forms of energy into mechanical energy. It is also referred to as the output power of the drive system.

The throttle is the device in the UAV power system that controls the output torque or power of the drive system.

For fuel engines, the throttle controls the fuel regulator.

For electric motors, the throttle controls the power regulator.

A characteristic curve represents the relationship between performance parameters of the UAV power system.

Typical characteristic curves include:

Throttle–thrust characteristic curve

Speed–thrust characteristic curve

Throttle–torque characteristic curve

Throttle–total power characteristic curve

Throttle–shaft power characteristic curve

The purpose of the test is to evaluate the matching between the propeller and the drive system under:

No inflow conditions (static testing)

Conventional low-speed wind tunnel conditions

The evaluation focuses on power performance and economic performance of the UAV power system.

The test specimen includes:

Drive system (engine or electric motor)

Propeller

UAV model

Control system

The test specimen shall be installed on a dedicated power system test bench using specialized fixtures. The installation status shall meet the requirements specified in the test task book or commission letter.

After installation, all sensor modules of the test bench shall be adjusted and verified. The software system shall be connected, and the basic parameters and testing information of the power system shall be set. The testing system must be verified to meet the requirements of the test task documentation.

When conducting propeller matching tests in a low-speed wind tunnel:

The installation of the UAV model and wind tunnel support must comply with relevant wind tunnel experimental standards.

After installation, the initial posture of the test piece relative to the wind tunnel coordinate system shall be measured and adjusted.

The initial model attitude deviation shall not exceed 0.3°.

Unless otherwise specified, the number of test specimens provided shall not be less than three sets.

The test task book or commission letter may specify additional requirements. Considering possible damage to connectors and accessories during testing, necessary spare and vulnerable parts should be prepared.

Temperature: 15–35 °C

Relative humidity: 20%–80%

Airflow velocity: less than level 3 wind

Environmental requirements shall comply with the provisions of Section 4.1 in GJB 4395-2002.

The force balance system shall comply with the provisions of Section 3.4 in GJB 6753-2009.

The model, typically consisting of an aircraft model and a propeller model, shall comply with Section 3.5 in GJB 6753-2009.

The model support system shall comply with Section 3.6 in GJB 6753-2009.

| Order number | Name | Use | Maximum distance | Accuracy |

|---|---|---|---|---|

| 1 | Force balance | Measuring force and torque | (0~2000)N, (0~500)N·m | Combined loading error 0.5%FS |

| 2 | Fuel flowmeter | Measuring the fuel flow rate of the engine | (0~100)kg/h | ±0.5% |

| 3 | Revolution speed transducer | Measuring propeller speed | (100~10000) r.p.m | ±1.0% |

| 4 | Cylinder temperature sensor | Measuring engine cylinder temperature | (-40~500)°C | ±1.0% |

| 5 | Exhaust temperature sensor | Measure engine exhaust temperature | (-50~1500)°C | ±1.0% |

| 6 | Fuel pressure transmitter | Measure fuel pressure | (0~0.5)MPa | ±0.2% |

| 7 | Line temperature sensor | Measure the temperature of the motor coil | (-40~150)°C | ±1.0% |

| 8 | Electrical temperature sensor | Measure the temperature of the motor governor | (-40~150)°C | ±1.0% |

| 9 | Current voltage measuring instrument | Measure the motor's operating voltage and WeChat Official Account "Feilong Electric" Current 7 | (0.1~60) V Linglu Fei 2.0 days | Voltage ±1.5% for mobile devices or systems |

When the propulsion system uses an electric motor as the power source, the test items shall include:

Rotational speed

Thrust

Torque

Current

Voltage

Shaft power

Motor coil temperature

Electronic speed controller (ESC) temperature

Vibration

Additional parameters may be measured depending on specific test requirements.

When the propulsion system uses a fuel engine as the power source, the test items shall include:

Rotational speed

Thrust

Torque

Shaft power

Engine cylinder temperature

Exhaust gas temperature

Fuel pressure

Instantaneous fuel consumption rate

Additional parameters may be included based on the test task documentation.

Before formal testing begins, it shall be confirmed that:

The testing environment meets specified requirements

The propulsion system is fully installed and calibrated

All sensors and data acquisition systems are functioning normally

Safety systems are operational

Testing shall only proceed after confirming that complete testing conditions are satisfied.

The test bench shall be equipped with:

Emergency fuel valve shutdown function

Throttle shutdown function

Physical emergency stop button

If any of the following situations occur during testing and pose a safety risk, the test shall be immediately interrupted:

Unexpected power failure

Fire alarm activation

Malfunction of control or data acquisition systems

Any other condition that may endanger personnel or equipment safety

Immediate shutdown procedures shall be executed to ensure system safety.

In the event of a major malfunction during testing:

The root cause shall be identified.

The fault shall be eliminated before resuming testing.

A determination shall be made regarding whether retesting is required based on the nature and impact of the fault.

If testing equipment fails:

On-site repair may be performed, or

Qualified replacement instruments may be installed.

All affected test items shall be retested to ensure data validity.

The test report represents the final technical output of the propeller power system matching test.

After completion of the experiment, the project leader shall compile a formal report that:

Meets the requirements of the test task documentation

Accurately reflects the testing process

Presents analyzed data and conclusions

Is delivered to the commissioning party

The test report generally includes:

Overview of the experiment

Test items, procedures, and methods

Test results

Analysis of experimental results

Conclusions

Supporting data sheets, characteristic curves, and calculation results shall be included as appendices where applicable.

Thrust is one of the most critical performance parameters affecting safe UAV takeoff.

The magnitude of thrust and the throttle–thrust characteristic curve directly influence:

Maximum takeoff weight

Payload capacity

Vertical climb rate

Maximum flight speed

Control margin and safety performance

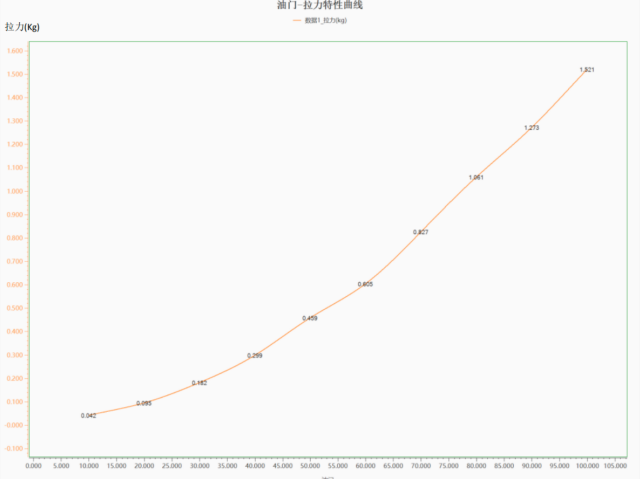

The throttle–thrust curve represents the thrust generated at different throttle positions.

For multi-rotor UAVs:

The curve is used to determine the throttle position corresponding to hovering thrust.

It verifies whether the propulsion system provides sufficient thrust for the UAV’s lifting requirements.

For fixed-wing UAVs:

The maximum thrust value and throttle–thrust curve are used to evaluate compliance with thrust-to-weight ratio requirements.

They also assess thrust output controllability.

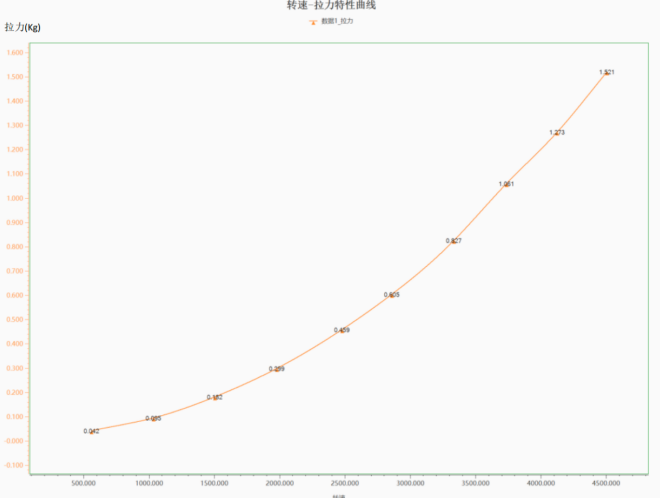

The speed–thrust curve represents the thrust generated by the propeller at different rotational speeds.

This curve is particularly important for:

Comparing different propeller designs

Evaluating variable-pitch propeller performance

Verifying whether thrust output meets performance indicators

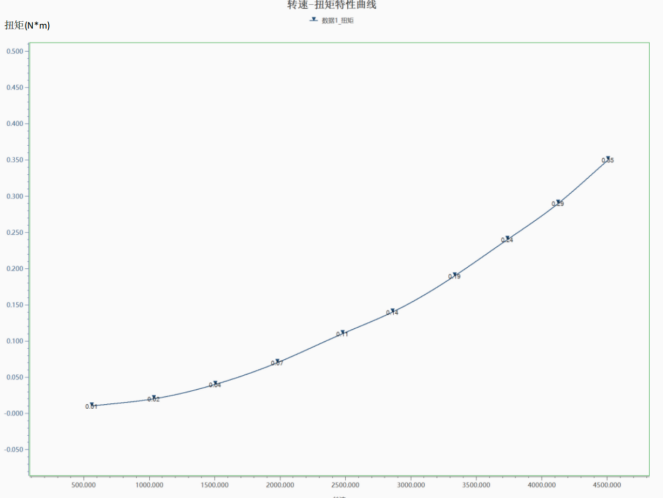

Torque represents the reverse torque generated by the propeller due to aerodynamic resistance.

The speed–torque curve describes the aerodynamic load characteristics of the propeller at different rotational speeds.

The counter torque generated by the propeller is balanced by the torque produced by the engine or motor. Therefore, torque represents the load imposed on the drive system.

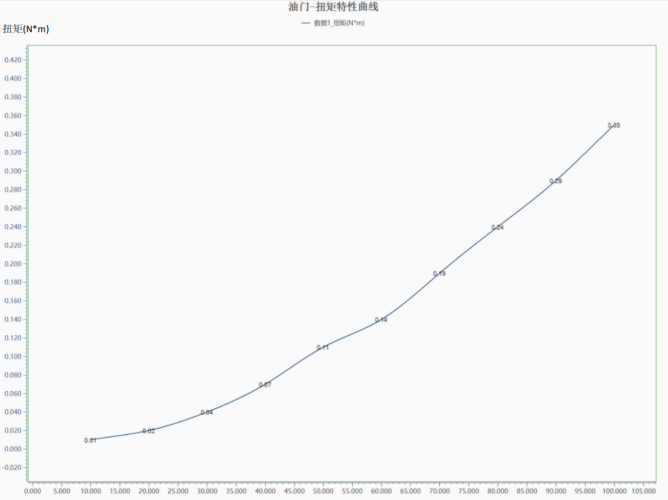

The throttle–torque curve reflects the torque output of the engine or motor at different throttle positions.

It is used to evaluate the power output characteristics and load adaptability of the drive system.

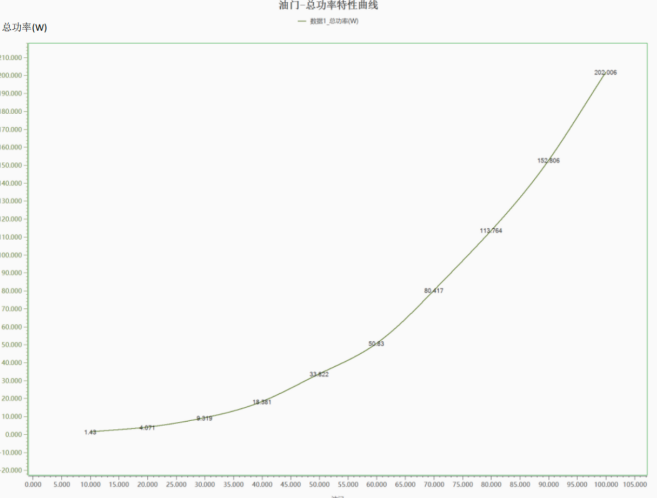

Total power represents the overall power consumption of the UAV propulsion system during operation, including:

Mechanical power delivered to the propeller

Thermal energy losses within the system

Total power is a key parameter in UAV endurance calculation.

The throttle–total power curve provides the power consumption corresponding to different throttle positions. By identifying the throttle level during hovering or cruising, endurance performance can be evaluated against mission requirements.

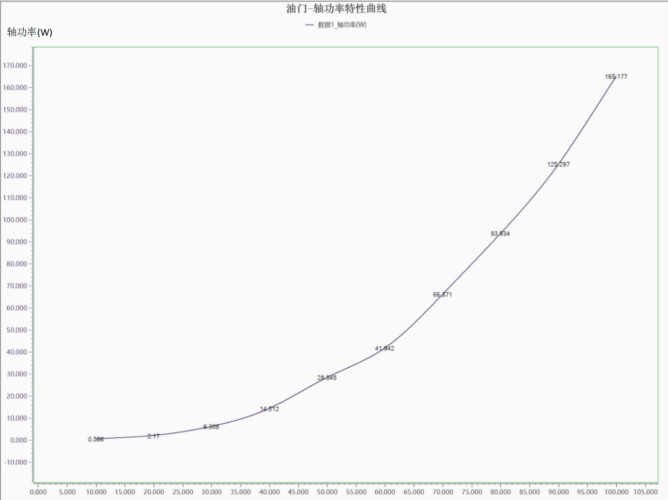

Shaft power refers to the mechanical output power delivered by the engine or motor to the propeller.

The throttle–shaft power curve represents shaft power at different throttle positions and reflects the effective power output capability of the drive system.

The characteristic curve examples corresponding to the above parameters include:

FIG A.1 Throttle–Thrust

FIG A.2 Speed–Thrust

FIG A.3 Speed–Torque

FIG A.4 Throttle–Torque

FIG A.5 Throttle–Total Power

FIG A.6 Throttle–Shaft Power

FIG A.1 Throttle-Thrust

FIG A.2 Speed-Thrust

FIG A.3 Speed-Torque

FIG A.4 Throttle-Torque

FIG A.5 Throttle-Total Power

FIG A.6 Throttle-Shaft Power

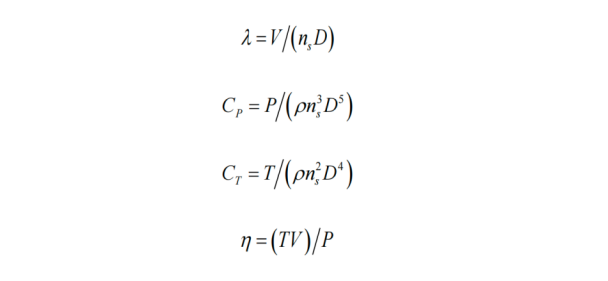

Note:

λ - forward ratio; CP - Power Coefficient; CT - thrust coefficient; η - Aerodynamic efficiency of propeller; D - propeller diameter, m; H - flight altitude, m; V - flight speed, m/s; ρ - air density, kg/m3; N - revolutions per minute, r.p.m; Ns - speed per second, r.p.s; P - power, kW; Q - torque, N·m; T - tensile force, N

UAV propeller–engine matching is a critical step in propulsion system validation. Accurate testing, standardized data processing, and comprehensive characteristic curve analysis are essential to ensure reliable thrust performance, load balance, and endurance capability under real flight conditions.

By implementing structured testing procedures and standardized evaluation methods, WingFlying provides professional UAV propulsion matching verification services covering static testing and low-speed wind tunnel environments.

For detailed technical consultation or customized propulsion testing solutions, please contact WingFlying’s engineering team.

E-mail: sandy@wing-flying.com

Add.: 7th Floor, B2#,Animation Building, Sino-Singapore Tianjin Eco-City