May. 12, 2022

The speed of the motor is usually measured in revolutions per minute, ie RPM. It's one of difficult tasks but also one of the most important things to know about your motor. It is essential to figure out the speed a motor rotates. This can be measured using a variety of tools. The easiest way is to use a tachometer. In some cases, this can be done using just a smartphone and an app. Skilled manufacturers and hobbyists can build their own devices to accomplish this task.

Motor speed measurements in revolutions per minute (RPM) are usually obtained optically or by contact with the motor shaft. Devices that use optical measurements require a reflective sticker to be placed on the rotating part of the motor. One device illuminates the motor, reads the reflection of the sticker and displays the RPM on the display.

Other devices require a mechanical connection to the motor shaft, usually by simply pressing the reading device onto the motor shafthttps://www.wingflyingtech.com/motor-test/wf-co-30kgf-coaxial-thrust-stand.html. A tachometer designed to measure motor speed can be purchased for about $40 or more, depending on the type and brand.

If a device specifically designed to measure RPM is not available, many other techniques can work. One DIY method is to use a strobe light that can be adjusted to a known value. In the absence of any tools, the easiest method (though not always the most reliable) is to use a phone app that will strobe the light on the phone at a specific rate to measure RPM.

In some cases, a computer with a sound card and appropriate software can be used instead of a frequency meter for this measurement. The goal is to receive a set of pulses to calculate one revolution of the motor. A Hall effect sensor, light blocker, or even just a microphone is also needed.

The Hall effect sensor works on a DC motor and uses the magnetic field variations of the motor to make the measurement. The light interrupter has two sides; one is the light source and the other is the receiver.

The microphone is less accurate due to ambient and other motor noise. To use the microphone, place a piece of tape on the motor shaft and place something, such as a finger, so that the tape touches it every time it turns, resulting in a humming sound that is picked up by the microphone. The output of one of these sensors is read as a pulse. If you have a multimeter with a frequency counter, the sensor can be connected directly to it. An oscilloscope will also work.

For computers that have neither a sound card, frequency counter, or oscilloscope, software that displays waveforms can also be used. Study the waveform of one of the sensors and look for a string of pulses; measure the space between the two pulses, i.e., the time taken for one revolution. To determine how many revolutions occur in a minute, divide 60 by the time of one revolution. This simple calculation will give you the RPM of the motor.

Using one of the above methods, it is perfectly possible to obtain a motor speed value with reasonable accuracy.

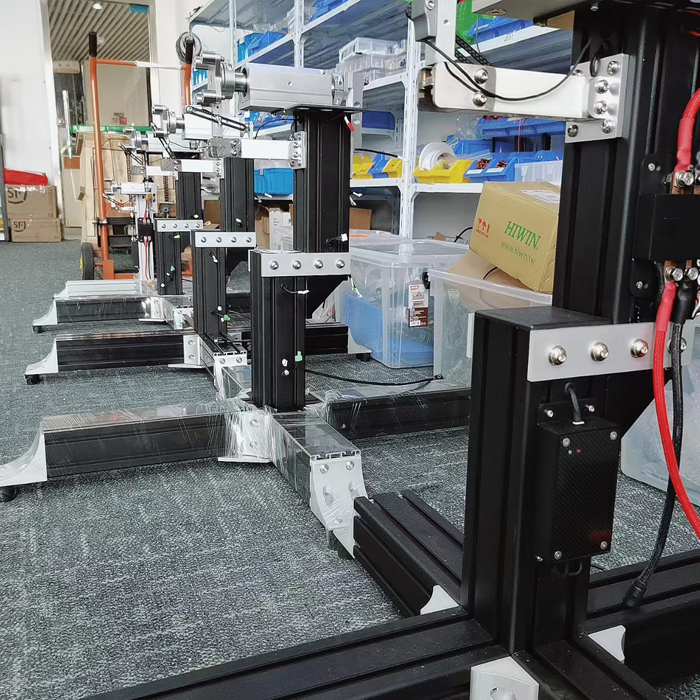

WingFlying offers various motor test stands to meet different test tasks for small size, medium size and heavy size of propulsion systems. Feel free to click the product you are interested in or directly contact us for further inquiries:

▶ WF-CO-30KGF Coaxial Thrust Stand

In addition to our standard offerings, we provide custom solutions to suit specific requirements. Download detailed specifications or request further information by contacting us.

E-mail: sandy@wing-flying.com

Add.: 7th Floor, B2#,Animation Building, Sino-Singapore Tianjin Eco-City