Aug. 20, 2025

When building a drone, RC model, or any device driven by a brushless DC (BLDC) motor, you will likely encounter the terms motor Kv and motor poles. These parameters are essential for describing motor characteristics and estimating overall performance. In this article, we look at what they mean, how to calculate and measure them, and how they are related.

How to Calculate Brushless Motor Kv

Understanding Motor Kv

Meaning of Kv Rating

Calculating Kv with Equations

Methods to Measure Motor Kv

How to Identify the Number of Poles in a Brushless Motor

Definition of Motor Poles

Motor Poles vs. Pole Pairs

Connection Between Motor Poles and Electrical Speed

Calculating Motor Poles with Equations

Measuring Motor Poles

Relationship Between Motor Poles and Kv

Verifying Results with a Thrust Stand

Motor Kv defines the relationship between peak voltage and rotational speed in a brushless motor under no-load conditions. Its unit is expressed as RPM/V, and it can be approximated by dividing the motor’s unloaded speed by the applied voltage.

In practice, the relevant voltage is the back electromotive force (EMF) rather than the supplied voltage.

Within a brushless motor, back EMF is a voltage generated in the opposite direction of the input current, induced by the coils moving through the magnetic field.

According to Faraday’s law, when a coil moves inside a magnetic field, it produces a flow of electrons within the coil, resulting in a voltage or EMF.

As the rotor spins, the back EMF produced is directly proportional to its rotational speed: higher RPM leads to higher back EMF. At maximum throttle without load (disregarding inertia), this relationship can be expressed as:

where = rotational speed.

The Kv rating indicates how many revolutions a motor will achieve for each volt applied. This value is useful when comparing motors of the same physical size that differ in internal design and performance.

In general, increasing the number of coil windings lowers the Kv value. Structurally, a low Kv motor contains more turns of thinner wire, which supports higher voltage at lower current.

By contrast, a high Kv motor uses fewer turns of thicker wire, allowing it to handle higher current with less voltage. The formulas in the following section provide a mathematical basis for this principle.

For practical applications, low Kv motors typically run at lower RPM while producing higher torque, making them suitable for larger propellers and heavier platforms. High Kv motors, on the other hand, achieve higher RPM with lower torque, fitting smaller, lighter, and faster propellers.

As a result, lightweight, high-speed models such as racing quads perform better with high Kv motors, whereas heavier, slower-moving setups benefit more from low Kv motors.

Example Comparison

A racing drone might use a motor rated around 2400 Kv, while a heavy-lift platform may rely on a motor closer to 100 Kv.

Another real-world difference can be seen between inrunner and outrunner motors. Inrunners usually have higher Kv values compared to outrunners of similar size. The larger rotor diameter of an outrunner accommodates more permanent magnets.

More magnets (or poles) → lower rotational speed → lower Kv. Conversely, the smaller diameter of an inrunner means a shorter distance per revolution, allowing it to spin more times for the same applied voltage.

It should be noted that Kv alone is not a complete measure of motor performance, as efficiency can vary between motors of the same Kv rating. Only direct testing can confirm how well a given motor performs.

Returning to the earlier formula:

We can rearrange the equation as follows:

To estimate Kv, the back EMF can be approximated by using the applied input voltage, which provides a reasonably close value.

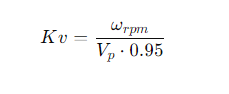

For greater accuracy, measure the voltage between two motor leads to obtain the RMS value, then multiply it by (≈1.414) to convert it into peak voltage. This peak voltage can then be substituted into the equation:

where = peak voltage.

The factor 0.95 adjusts for deviations from the theoretical model, giving results that align more closely with experimental measurements. This correction is commonly applied in Kv calculations.

Experimental measurement is often the most reliable way to determine the actual Kv of a motor. In many cases, there are noticeable differences between the labeled Kv and the measured value, something you may also observe.

One approach is to run the motor in a no-load test using appropriate measuring equipment and software. By entering the number of poles in the setup, connecting the motor without a propeller, and running the test, the system can automatically calculate the Kv once the process is complete.

Even when a motor comes with a specified Kv rating, it is worthwhile to measure it yourself to verify whether the real-world performance matches the specification.

Inside a brushless motor, several magnets are arranged around the rotor’s circumference. These magnets are referred to as the motor’s “poles.” When current flows through the stator windings, the electromagnetic fields interact with the rotor magnets, causing the rotor to spin.

In the illustration, the blue rotor represents the permanent magnets of an inrunner motor (left) and an outrunner motor (right), while the green stator contains the electromagnetic coils.

Each magnet on the rotor has a north and a south end, but only one end interacts with the stator at a time. The number of north-facing and south-facing magnets is equal, and each combination of a north and south magnet is called a “pole pair.”

A single pole pair consists of two poles. For example, a motor with 8 poles contains 4 pole pairs. This also explains why motors almost always have an even number of poles (2, 4, 6, 8, etc.), as every magnet requires an opposite pole.

Examples:

2-pole motor → 1 north magnet + 1 south magnet → 1 pole pair

8-pole motor → 4 north magnets + 4 south magnets → 4 pole pairs

Motor speed is inversely related to the number of rotor poles. This relationship can be expressed as:

Where:

= synchronous speed (RPM)

= frequency of the three-phase power supply (Hz)

= total number of poles

Alternatively, using pole pairs:

Where:

= synchronous speed (RPM)

= frequency of the three-phase power supply (Hz)

= number of pole pairs

Since each permanent magnet on the rotor represents a pole, the simplest way to determine the total number of poles is by counting the magnets.

This can be done if the motor’s interior is visible or if the outer casing can be removed. If the casing cannot be removed, counting can be challenging due to the small size and large number of magnets.

Some simple approaches have been suggested, such as moving a magnet around the rotor to detect points of attraction and repulsion. This method is most practical for outrunner motors, where the magnets are located on the rotor’s outer surface near the stator.

Caution is advised, as strong external magnets may partially demagnetize the rotor’s magnets.

Another method, which requires more effort and equipment, involves measuring the motor’s speed and the power supply frequency, then using the following formula to calculate the number of poles:

Where:

= number of poles

= frequency of the supply or back EMF (Hz)

= motor speed (RPM)

To determine motor speed, you can use a tool to back-drive the motor (for example, a drill) and a tachometer to measure rotations per minute. Simultaneously, an oscilloscope or similar device can measure the back EMF frequency. Input these measured values into the equation to calculate the total number of poles.

The easiest way to determine the number of poles is often to use a test stand with automated calculation.

By entering the motor’s Kv rating into the pre-programmed script and running the motor at full speed (without a propeller), the system can automatically calculate and display the pole count within a few minutes.

Recommended test stands for automated Kv and pole measurements:

Test Stand A (≤5 kgf / ≤2 N·m): WF-EDU-01 Motor and Propeller Test Kit — 10 kgf / ~5 N·m.

Test Stand B (≤15 kgf / ≤8 N·m): LY-30KGF Thrust Stand — 30 kgf / ~20 N·m (recommended for margin).

Test Stand C (≤50 kgf / ≤30 N·m): WF-EN-15 Engine Test Bench — matches 50 kgf class.

Test Stand D (≤150 kgf / ≤150 N·m): WF-EN-50 Engine Test Bench — 150 kgf / 150 N·m.

Test Stand E (≤500 kgf / ≤1500 N·m): Custom Test Stand / Onboard Thrust Test Kit — custom design for ultra-high thrust.

Need coaxial testing? See the WF-CO-30KGF Coaxial Thrust Stand.

E-mail: sandy@wing-flying.com

Add.: 7th Floor, B2#,Animation Building, Sino-Singapore Tianjin Eco-City