Mar. 25, 2022

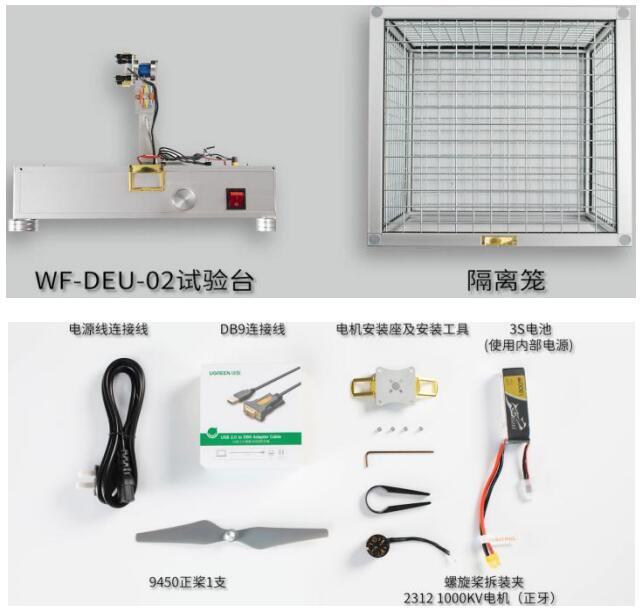

Preparation of experimental equipment and tools;

WF-EDU-02 test bench: main body, isolation cage, power line, data line;

Power system: 20A electric adjustment, 3S battery (can be replaced by the internal power supply of the test bench), a set of motor and propeller: motor model is 2312-KV1000, propeller model is 9450;

Other assembly tools: hexagon socket, bolt, propeller assembly clamp.

Figure 2.1 Experimental equipment and tools

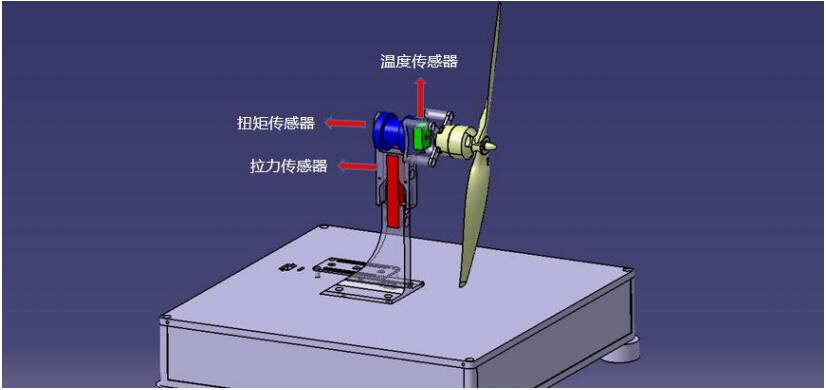

FIG. 2.2 Three-dimensional schematic diagram of the sensor on the test bench

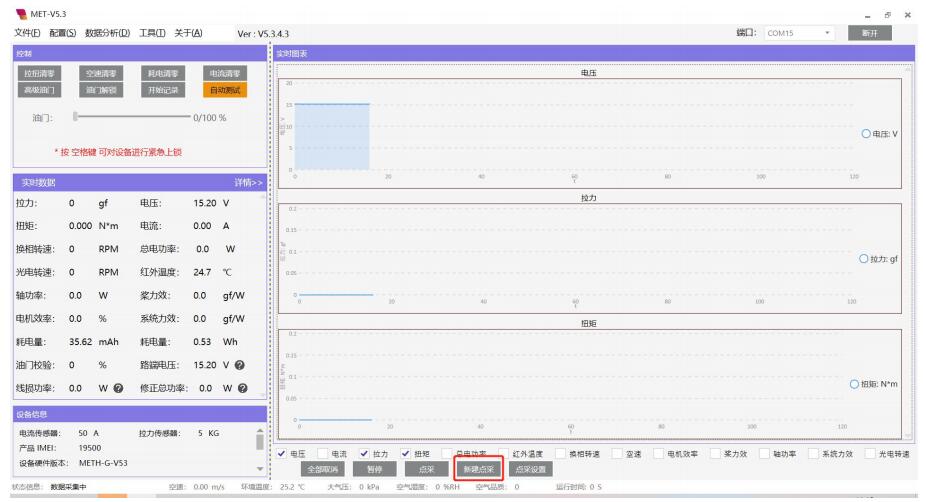

(1) Refer to the operation experiment steps of experimental course 1 and 2 to complete the installation of motor and test bench, test bench electricity, software connection, electric adjustment stroke calibration, motor steering adjustment and propeller installation, carry out safety protection Settings, and adjust the test voltage to 11.4V.

(2) Click the test information, fill in the test information in the software test information bar, and save it.

Figure 2.3.1 Filling in test information

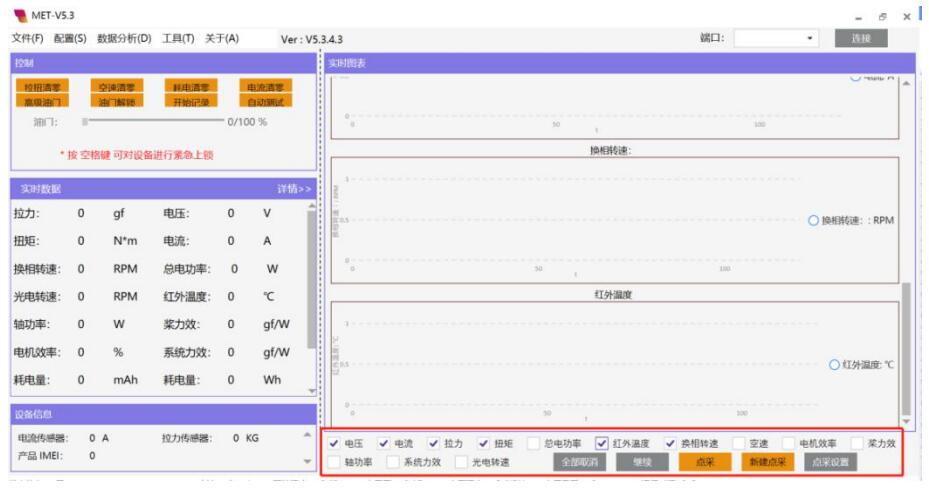

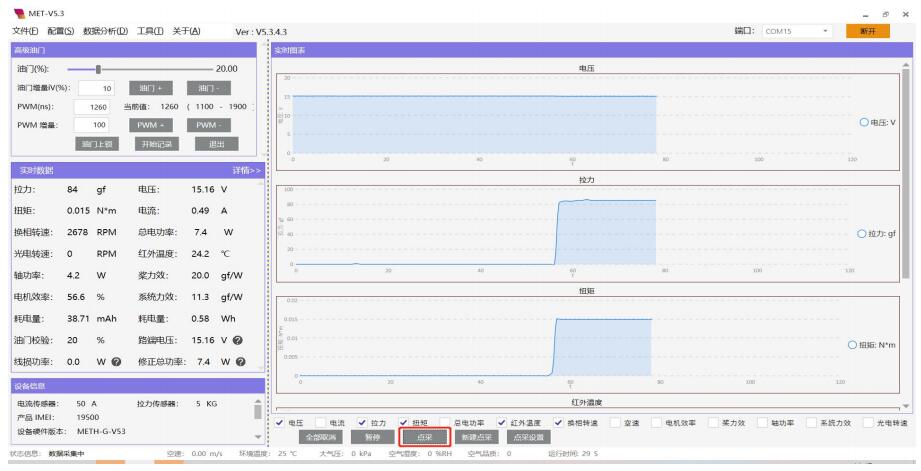

(3) Check the icon below the real-time chart of the test bench software to display parameters (tension, torque, voltage, current, commutation speed, infrared temperature). On the right of the real-time chart, you can view the real-time chart of each parameter.

Figure 2.3.2 Real-time icon check position diagram of test bench

(3) Set up point collection file: Click the new point collection at the lower right of the test platform software, the software will automatically set up point collection data file and record the current test data of the first group.

Figure 2.3.3 New point collection file

(4)Click the accelerator to unlock, click the new point on the lower right, and drag the accelerator to 20%, 30%, 30%, 40% and 50% respectively (for accurate throttle control, click the advanced throttle in the control window, set the throttle increment to 10%, and achieve accurate throttle control through throttle + and throttle-). Each throttle position stays for about 10 seconds (the data is stable), each time click click, the software will automatically record the current test of a group of data. Test done, hit the throttle to lock.

FIG. 2.3.4 Advanced throttle setting and control schematic diagram

FIG. 2.3.5 Hold each throttle point for about 10 seconds and click on the throttle point

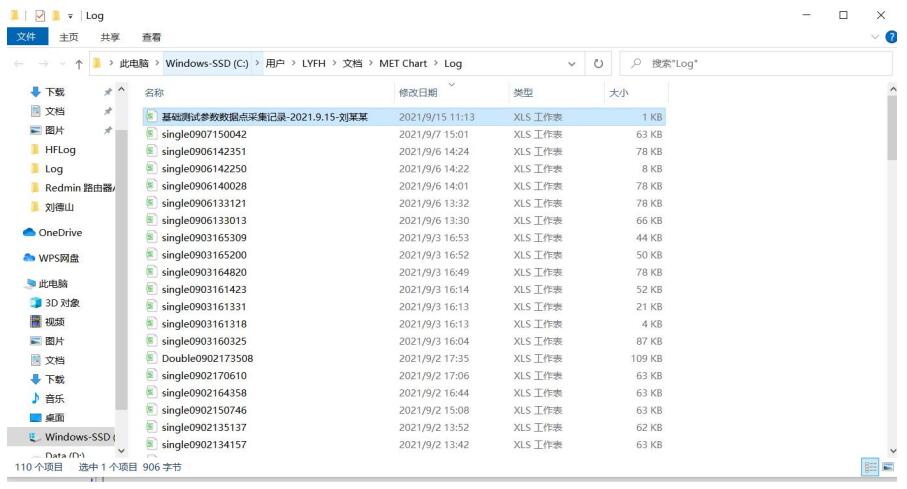

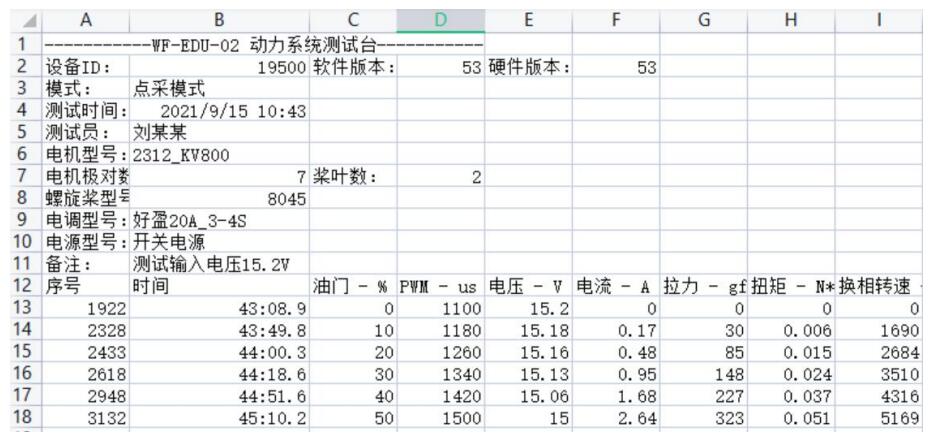

(5)You can open the saved directory for new file viewing by using the file menu in the toolbar. Rename the first file in the directory (the file name is single Spot+ creation time) to "Basic test parameter Data Point Collection Record - Time - Tester". Double-click and open the renamed file to view the test data.

Figure 2.3.6 Point data file renaming

Figure 2.3.7 Final test data

The experiment of this course is divided into two parts: the first part is the explanation of experimental principle, which comprehensively explains the basic test parameters of the dynamic system and the test parameters of the dynamic test bench.

Through the explanation of experimental principle, we can have an overall understanding of the basic parameters of the test. Second, the experimental training part, through the familiar with the location of each test sensor layout, the whole test instrument has a clear understanding. Test, observe and record each parameter, and master the data test method of dynamic system test data.

Note: After the experiment, please restore the experiment equipment to the state before the experiment, and put the experiment equipment and tools back to the designated position.

E-mail: sandy@wing-flying.com

Add.: 7th Floor, B2#,Animation Building, Sino-Singapore Tianjin Eco-City