Jun. 22, 2022

A question we get fairly often is: “Why do you need to measure torque when doing motor or propeller testing?” This is often followed by: “How can I measure torque?”

These are both important questions for drone designers who want to get the most out of their designs. It ultimately comes down to measuring your motor’s efficiency by comparing the input to the motor with its output.

There are two key variables when it comes to the propeller: the first is the rotation speed and the second is torque. When you multiply rotation speed and torque together, you obtain mechanical power.

If we look at how a propeller and motor are connected, we see that the only connection or “information” sent from the motor to the propeller is RPM and torque.

Figure 1: Drone motor connected to three blade propeller

At the other end of the motor, electricity enters from the battery or power source. We can therefore consider the motor a machine that transforms electricity into RPM and torque or electrical power into mechanical power.

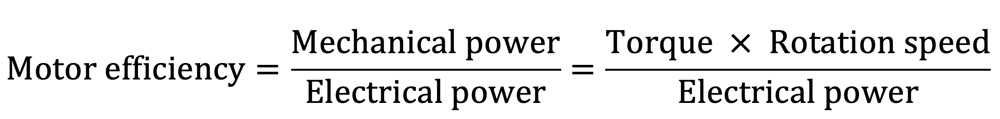

This brings us to our key efficiency formula. When we measure torque, we’re able to obtain mechanical power, which we can divide by the electrical power to obtain efficiency:

There are design trade-offs that come with increasing torque and RPM, and testing multiple propellers is the best way to find the most efficient motor-propeller combination for the type of flight you want to do.

If we can keep the same propeller efficiency, increasing the ratio of mechanical power to electrical power means that air vehicles will be able to fly longer and carry more payload.

There are a few ways to measure torque, and in our test stands we use a steady-state solid system, which means that there are no moving parts. This is great because it reduces hysteresis and vibration.

In our test stand we have three load cells that each measure two forces, so there’s a total of six forces measured. The image below shows our coaxial test stand, so there are three load cells for each propulsion system, or six load cells total. After our calibration procedure, we’re able to measure the exact torque and thrust that is applied to the motor mounting plate by the motor.

Now that we have measured torque, we also need to measure the motor’s RPM / rotation speed to fill in our equation for mechanical power.

This is achieved by using a small infrared RPM sensor that can sense when a piece of reflective tape passes in front of the sensor. The accompanying electronics use a counter to determine how many times the reflective tape passed the sensor, which allows it to calculate the rotation speed. The rotation speed can also be measured electrically, using the ESC signal. This method is simpler mechanically, but it is more sensitive to the motor load and size.

Multiply this figure by rotation speed and divide the product by electric power to get mechanical power.

Measuring the system’s torque is essential when designing a propulsion system, as it allows you to measure the motor efficiency separately from the propeller efficiency. Here we covered how you can measure torque and how to use this information to build a more efficient drone.

Almost all of WingFlying test stands measure torque and thrust: send us an email if you are interested in testing motors and propellers yourself!

E-mail: sandy@wing-flying.com

Add.: 7th Floor, B2#,Animation Building, Sino-Singapore Tianjin Eco-City